Many solutions are only viable for the short-term and then fail due to a lack of technical understanding.

At Miwatek, we know that selecting and implementing the appropriate solution is only part of the mine water problem. It also requires operation and maintenance to ensure the successful treatment of mine water.

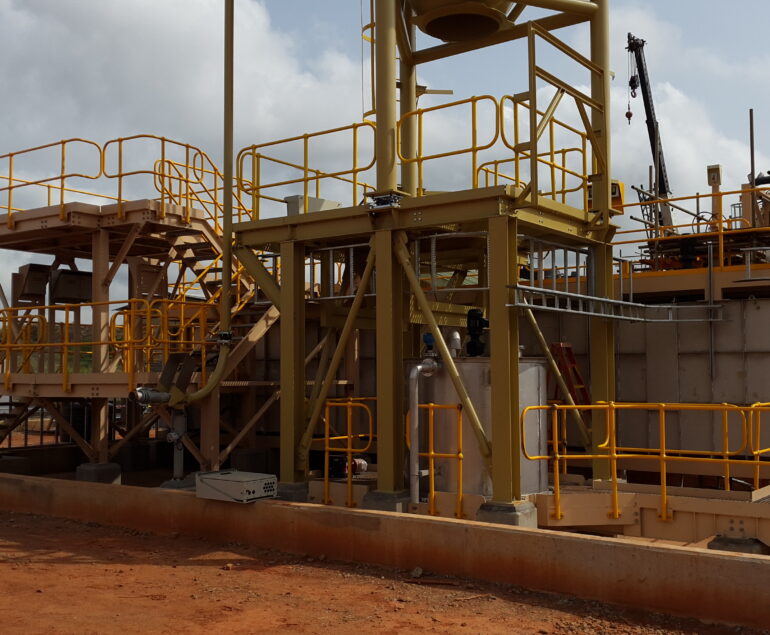

We have a proven track record in operating and maintaining mine water treatment plants. Our strong technical team allows us to deploy relatively inexperienced operations teams. The technical team supplies daily performance and operational input to the operations team while also optimising and troubleshooting the plant.

The technical team can also assist the client operators to sustainably operate the plants. We are here to supply the appropriate technical solution while ensuring operation and maintenance for ongoing on-site success.

Operations and Maintenance

Our Performance and Operational Services

General O&M

General O&M. Miwatek has an experienced team responsible for the day to day operations and maintenance activities. With safety as our key value, we have optimised the size and specialities of the teams. Our technical team supports the O&M team by:

- Optimizing operations

- Troubleshooting

- Providing guidance for operating and cleaning activities

- Spares management

- Procurement support

Current operating plants – Ahafo and Akyem. Each site has 6 operations and 3 maintenance staff with a supervisor and manager.

Advanced Remote Monitoring and Operational Management

Miwatek extends its commitment to operational excellence by integrating advanced remote monitoring techniques that ensure our treatment plants operate at peak efficiency and compliance. Our approach combines sophisticated technology with proactive management to significantly enhance operational outcomes.

Key Operating Parameters Remotely Monitored:

| Parameter | Operational Impact |

| RO Normalized Flux and Pressure Drop | Monitoring performance decline informs optimal clean in place (CIP) times to maintain system balance and efficiency. |

| UF Transmembrane Pressure (TMP) | Tracks fouling rate to optimize physical and chemical cleaning frequencies. |

| Feed Pressure | Ensures membrane operations remain within safe and efficient pressure limits. |

| Flow Rate | Essential for managing system throughput and operational pace adjustments. |

| Dosing Rates | Manages chemical usage efficiently, keeping treatment effective and cost-effective. |

| Sulphate Reduction | Monitors effectiveness of precipitation reactors, crucial for optimizing hydrated lime consumption. |

| Membrane Rejection | Maintains desired permeate purity and system efficiency, critical for quality control. |

| Recovery | Optimizes the volume of treated water, enhancing resource management and sustainability. |

| Plant Availability | Guarantees high readiness and reliability for continuous plant operations. |

| Cyanide Destruction | Ensures environmental compliance and safety in discharge levels. |

Leveraging our bespoke app, Miwatek captures and analyzes a wealth of operational data daily. This powerful tool not only streamlines data management but also enhances performance monitoring, enabling our engineers to focus on strategic optimization rather than routine data collection. This shift significantly reduces operational costs and boosts long-term reliability and compliance.

Furthermore, Miwatek is dedicated to transparency and continuous improvement. We provide our clients with comprehensive daily, weekly, monthly, and yearly performance reports, detailing everything from recovery rates and stock levels to maintenance reports. Additionally, we regularly provide environmental compliance reports to environment protection agencies, ensuring all operations meet the strictest standards.